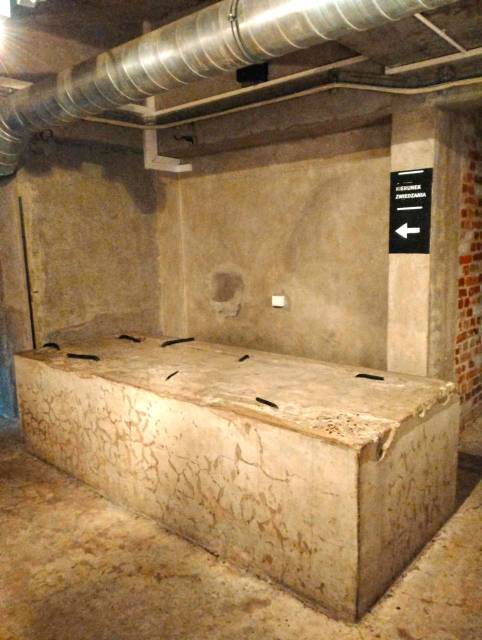

In glass columns, nitroglycerine was combined with water. Through this rinsing process, the nitroglycerine was purified and pre-stabilised for further transport. On leaving the building, the nitroglycerine in water suspension flowed by gravity to the nitroglycerine stabilisation building. In the stabilisation building, the nitroglycerine was separated from the production water. It was mixed with new, clean, softened water in special tubs. It was then transported to the next building, where the so-called powder cake was produced.

Places

Places Guides

Guides Map

Map Outdoor games

Outdoor games Trails

Trails Events

Events Mobile app

Mobile app Contact

Contact